Veneer and Lacquer Sanding

Furniture manufacturers and designers present new living trends every year. Whether furniture with unusual surfaces or with the latest trend colors to ensure the desired trend, pieces of wood covered with veneer or lacquer must be sanded professionally. In view of the low layer thickness and the high sensitivity, the materials, wood refiners have high demands on the grinding materials in the area of precision and performance.

CUMI AWUKO Abrasives GmbH

At AWUKO Abrasives, our top priority is to maximize the speed and quality of your woodworking projects while increasing the productivity and bottom line of your business. That's why we manufacture a range of exceptional woodworking grinders that use the best materials and designs in the industry to develop machines that meet and exceed your production needs. We are also proud to provide advice or advice that your team needs to expand their understanding and expertise in all forms of woodworking. That is why today we will guide you through the best ways to sand veneered or lacquered wood quickly and effectively.

Sanding veneers

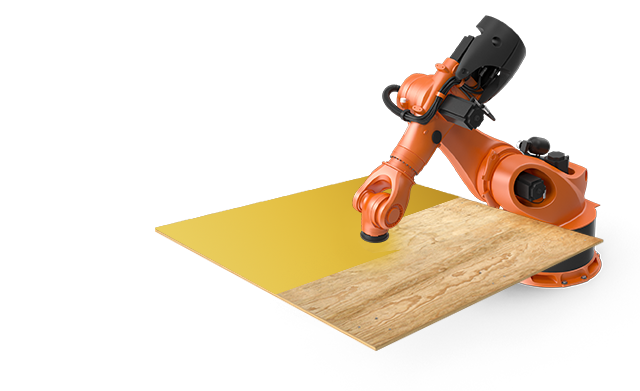

Veneer consists of a thin layer of wood that is applied to the surfaces of wood-based materials for the decorative finishing of furniture. The usually very thin veneer layers are very sensitive and must be sanded with the utmost care. To avoid irreversible damage and finally achieve a perfect finish, we recommend grit sizes over 120, which are gradually increased in grinding cycles in order to gradually achieve a finer result in the process. Industrial grinders or grinding robots with segmented wide belts with rotary brushes should be used for large-area veneered pieces such as furniture.

The paint grinding

In the future, surface specialists will rely on automated painting techniques using robot technology. Six-axis painting robots with 3D part recognition are used for this. The programmed robots paint components from window and furniture manufacturers fully automatically at rapid speed and constant quality. Due to the precise application of paint, painting robots are becoming increasingly popular, especially for companies in the industrial window and furniture coating sector. Due to the precise and automated paint application, the sanding result has an enormous influence on the quality of the painting process.

NC lacquers (nitrocellulose)

Nitro lacquer or NC lacquer or CN lacquer contain nitrocellulose as a film former, a physically drying cellulose derivative. Mostly the nitrocellulose is combined with alkyd resins. These paints are referred to as nitro combi paints or NC combi paints. Nitro lacquer is usually solvent-based. Nitro lacquers are mainly used for indoor use. They can withstand high mechanical loads, but are sensitive to the effects of the weather. Fast drying and easy to process, nitro lacquer is used for furniture, woods, metals or musical instruments. The elasticity of all nitro lacquers decreases with increasing layer thickness. Therefore, layer thicknesses that are too high should not be applied. When processing nitro lacquers, ensure good ventilation. So-called nitro thinner or nitro solution is used to dilute nitro lacquer or to loosen or clean work equipment.

Water-based paints

A distinction is made between water-soluble and water-dilutable paints in water-based paints. In the case of water-soluble waterborne paint, the binder is dissolved in the paint, while in the case of water-dilutable water it is only distributed in the paint. The latter variant is also called dispersion varnish. Suitable water-based paints are available for inside and outside, for painting metal, wood, plastic and for special tasks such as car painting. Variants with various binders such as alkyd resin and acrylate resin are obtained. In addition, water-based paints are offered as 1k and 2k paints. With the often particularly resistant 2-component paint, there are two components (base paint and hardener) that are only mixed before painting.

A distinction is also made between water-based varnish based on the degree of gloss, which ranges from dull matt to high-gloss. Depending on the requirements of the paint layer, other properties may be important, such as high scratch and impact resistance or openness to diffusion, so that water vapor escapes through the paint layer.

UV-hardened paints

UV-hardened paints can be used in a wide variety of areas and industries. Among other things, UV lacquers are used in the priming of furniture parts as well as in the automotive sector and in general for surfaces such as plastic and glass substrates. The curing time is only a few seconds, which means that processes can be accelerated and made more efficient. In addition, the UV hardened surfaces are durable, abrasion and scratch resistant.

Polyester paints (unsaturated polyester)

Polyester high-gloss paints, also known as "polyesterine" (polyester filler), do not contain paraffin and can be sanded easily by hand, similar to polyurethane primers. They differ from them in their high solids content and thus in their higher filling capacity with fewer applications. Since polyester fillers are particularly resistant to falling and dissolving, they are suitable for closed-pore lacquering (clear lacquers or colored lacquers), especially for lacquering kitchen and bathroom furniture. Due to their high thixotropy, they are also suitable for painting molded parts and even for vertical painting applications.

PUR (polyurethane)

Polyurethane paints (PUR paints) belong to the reaction paints. A distinction is made between PUR lacquers in one and two-component lacquers. One-component paints already contain a hardener in addition to the base paint. Polyurethane paints harden by exposure to air humidity or by heating to at least 150 ° C. Two-component lacquers are mixed from hardener and base lacquer directly before processing. The properties of polyurethane paints (particularly hard, abrasion-resistant and resistant to water, oils and chemicals) mostly determine the area of application (e.g. parquet, stairs, table tops). In addition to wood, other building materials (concrete, plastics and metals) can also be coated with PUR lacquer. In addition, PUR lacquers are also suitable for priming and painting as well as a barrier and insulating primer.

Glazes

Glazes are particularly suitable for woods that are used outdoors. Weather influences such as sun exposure, UV exposure, moisture but also insects, blue fungus and other fungi can destroy the fabric structure of the wood.