Sanding Discs and Wheels

AWUKO sanding discs are ideal for dry sanding many surfaces where quality of finish is of primary importance. The choice of backing type and attachment option generally guides which product is best suited to the application.

CUMI AWUKO Abrasives GmbH

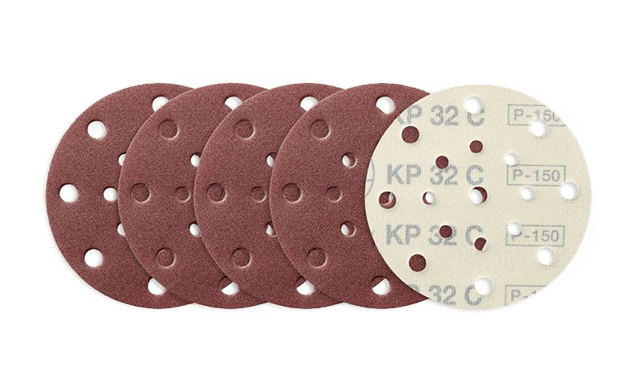

Paper Discs

Paper discs are the traditional dry sanding product for random orbital and rotary sanders. Available in adhesive back and hook & loop attachments in a variety of sizes, hole patterns and abrasives types to give you the highest performing and broadest selection for light stock removal to fine finishing on wood, plastic, fiberglass, composite, primer and sealers. For maximum dust extraction, our Cyclonic technology extracts 60% more dust for cleaner work surface and environment.

Cloth Discs

Cloth discs are the traditional metal sanding product on random orbital and stationary disc sanders in conjunction with a rubber back-up pad that delivers the rigidity for hard to grind alloys and steels. They offer strong tear and edge-fray resistance.

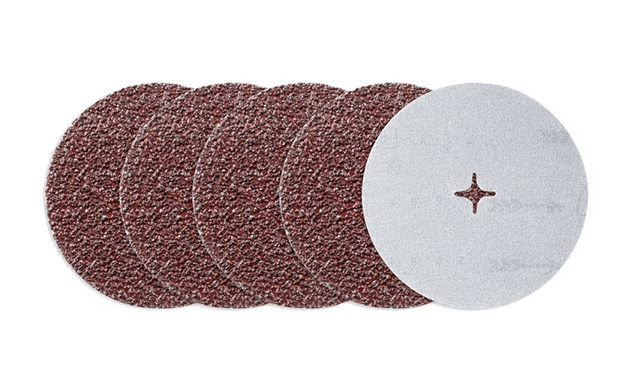

Fiber Discs

Fiber discs are the most classic of grinding product designs using a heavy-duty coated abrasive disc with resin over resin construction on heavy-duty vulcanized fiber backing. Ideal for general purpose applications ranging from heavy stock removal to surface blending used with a back-up pad on portable angle grinders.

Flap Discs

Flap discs offer right angle grinding versatility with a product that can grind and finish in a single operation. The abrasive flaps are adhered to a rigid backing plate. It is the back plate that provides stability during operation with cooler cut, less vibration and smoother finish without gouging. Flap discs are well-suited to stock removal through blending applications.

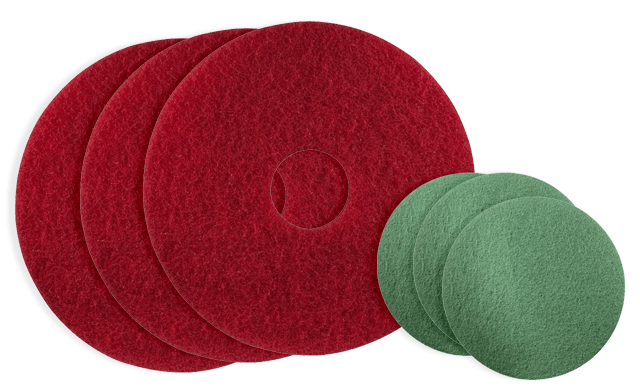

Surface Conditioning Discs

Cloth discs are the traditional metal sanding product on random orbital and stationary disc sanders in conjunction with a rubber back-up pad that delivers the rigidity for hard to grind alloys and steels. They offer strong tear and edge-fray resistance.

Foam Discs

Foam discs are engineered for moist finishing clear coats, varnishes, composites and gel coats to produce a semi-polished surface for quick and easy buff out. The design provides equal pressure that eliminates pigtails and provides a uniform scratch patter. The integrated foam backing conforms to contours.

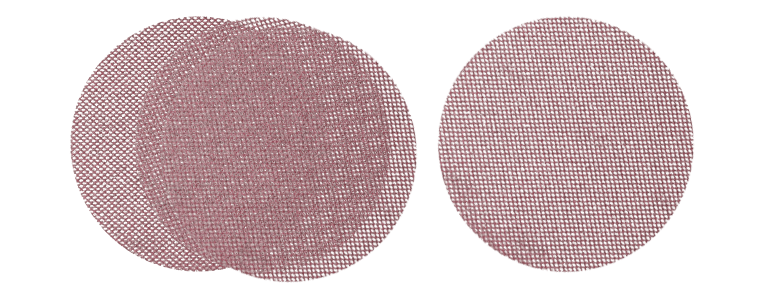

Net Discs

Net discs are designed with an open mesh backing allowing for maximum dust extraction, creating a cleaner, healthier work environment. These discs are made to last and produce a fine scratch pattern for a better finish.