Stone and Glass Sanding

AWUKO's glass and stones grinding solutions are suitable for many surfaces. Whether building facades, glass doors as well as ship and any transport vehicle windows.

CUMI AWUKO Abrasives GmbH

Important information for optimal glass grinding

- The individual grinding steps must be carried out carefully since there is an immediate risk of optical refraction.

- The final polishing must be carried out persistently and with a special polishing agent.

- Defects in the optical driver's field of vision must not be ground or polished on vehicle windshields.

- Safety first! Always use a dust protection mask.

The right grinding of marble / stones

We often understand the term marble as recrystallized limestones. These are often different in origin and color. We generally recognize marble by the stone pattern. Marble is referred to as such if a rock consists of at least half of calcite, aragonite or dolomite.

Grinding of marble

Common types of marble are Carrara marble, Thasos, Serpentines, Comblanchien marble or Noir de Mazy marble. The colloquially designated types of marble such as limestone, onyx, travertine, etc. are actually soft rocks and most soft rocks are called marble in everyday usage. In addition to naturally occurring marble, we can also determine the existence of composite marble and granite (or terrazzo), which actually contain marble pieces that are held together by a cement-based frame.

The greatest advantage of marble is that by simply sanding the old shine of the marble can be achieved, even if it is very old marble.

Depending on the condition of the floor, the standard renovation treatment for marble consists of at least two grinding processes and subsequent crystallization treatment with powder in order to achieve a high degree of gloss. In areas with frequent use and the marble resistance is limited, it is recommended to carry out the crystallization regularly (every year) in order to achieve an even smooth and brilliant surface and an improved resistance.

Regardless of the surface condition, marble always remains susceptible to chemical attacks (acidic or alkaline).

Therefore marble is sensitive to:

- Acids such as fruit acids and vinegar

- Alkaline bases, strong soapy water and wash water

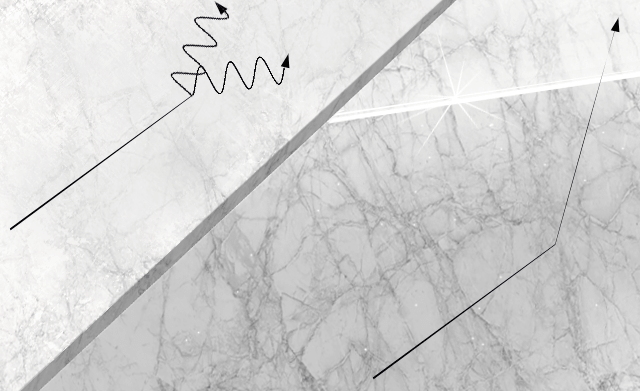

The following illustrations show how the light is optimally reflected when the stone is perfectly smooth.

Under the term marble we often understand recrystallized limestones. These are often diverse in origin and color. We generally recognize marble by the presence of veins or a marble pattern.

Marble can be sanded dry or wet. When grinding dry, always pay attention to the high temperatures that occur. The resulting dry sanding dust must be contained by good ventilation and vacuum systems. With wet grinding, water is added manually or automatically to the grinding process. The water prevents high temperatures and the dust from whirling around. First of all, sanding means that the floor is "machined" with a sanding element and "smoothed" again with step by step finer sanding material. A mostly rotating machine cuts the stone to compensate for the scratches and grooves layer by layer with the intact surface. Sanding also allows you to remove the edges between the tiles (edge sanding), but also to remove stains and cracks on the surface.

Mechanical polishing of marble

Mechanical polishing is a process similar to grinding stone / marble. The only difference is the size of the abrasive grains used. These are much finer than the abrasive grits. Each polishing step smoothes scratches in the stone until even the finest scratches are leveled out. With these individual steps, the roughness of the stone is removed until gloss is created.